FOB Price

Obtenir le dernier prix1.11 ~ 1.41 / Square Meter

|Minimum Order

Localit�:

-

Prix de commande minimale:

Commande minimale:

100 Square Meter

Packaging Detail:

according to the customer

Delivery Time:

within 7 days

Supplying Ability:

10000 Square Meter per Month

Payment Type:

D/P, D/A, L/C, T/T, Western Union, Money Gram, PayPal

Personne à contacter Ms. zhang

NO22North Industrial Park, Hengshui, Hebei

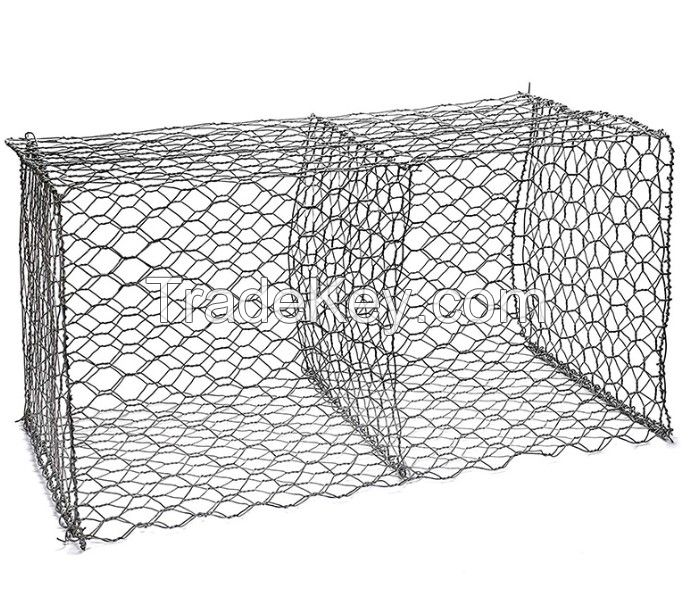

The stone cage net is made of high corrosion resistance, high strength, low carbon steel wire with extensibility or covered with PVC steel wire using mechanical weaving, the use of the net made of box structure is the stone cage cage. According to ASTM and EN standards, the diameter of the low carbon steel wire used varies according to engineering design requirements. Generally between 2.**4.0mm, the tensile strength of stone cage mesh steel wire is not less than *8kg/m2, metal coating weight is generally higher than **5g/m2, stone cage mesh edge line diameter is generally greater than the diameter of the network cable. The length of the double stranded part shall not be less than *0mm to ensure that the metal coating and PVC coating of the stranded part of the steel wire is not damaged.

The characteristics of

1. The flexible structure can adapt to the changes of the slope without being destroyed, and has better safety and stability than the rigid structure; 2. Strong anti-erosion ability, can withstand the flow speed up to 6m/s; 3. The structure is essentially permeable, which has a strong tolerance for the natural action and filtration of groundwater. The suspended substances and silt in the water can be deposited in the stone filling joints, which is conducive to the growth of natural plants and the gradual restoration of the original ecological environment.

The stone cage net is to fill the stone fixed in place of the wire or polymer screen format. A wire cage is a structure made of woven mesh or welded wire. The two structures may be electroplated, and the woven wire box may be separately coated with PVC. With weathering resistant hard stone as filler, it will not be eroded in the stone box or stone cage sinking row and soon broken. Equipped with different types of stone cage has different characteristics. The multi-angle stone can be well interlocked with each other, and the stone cage filled with it is not easy to deformation. In landscape engineering, highway slope protection, dam revetment and steep slope greening has always been a headache for engineering and technical personnel. For years, they have been exploring a process that can not only meet the requirements of mountain and shoal stability protection, but also achieve the effect of greening the environment, while also economical and convenient. Gradually, this process began to surface, it is the ecological stone cage net application process. Ecological stone cage net application process is to use high strength galvanized steel wire woven into different specifications of the rectangular cage, the cage filled with stone structure. After this structure is applied to the protection of the bank slope, under the double action of man-made and natural factors, the gaps between the stones are constantly filled with soil. The seeds of the plants gradually take root in the soil between the rocks and grow strong. The roots hold the rocks and soil firmly in place. In this way, the slope protection and greening can be achieved, and the effect of improving ecology and conserving water and soil is also very significant.