Prix FOB

Obtenir le dernier prix( Negotiable )

|1 Unit Minimum Order

Pays:

South Korea

N ° de modèle:

ANYOXY

Prix FOB:

( Negotiable ) Obtenir le dernier prix

Localité:

Republic of Korea

Prix de commande minimale:

-

Commande minimale:

1 Unit

Packaging Detail:

Box

Heure de livraison:

30 to 45 days

Capacité de Fournir:

999 Unit per Day

Payment Type:

T/T

Groupe de produits :

South Korea

Personne à contacter Ms. Ella

309 Mokdong dong ro, Seoul, Yang Cheon Gu

Introduction

1. General Description of ASPE O2 Generato

This process is completed over and over again until the demand for

oxygen is met. As for ASPEs designed and manufactured oxygen

generators, these has constructed technical trust on

gas-engineering from domestic and overseas companies based on the

best duration and reliance,

and excellent and economical efficiency considering on-site

condition from its engineering step.

The ASPE generator consists of two tanks filled with a

sieve. As high pressure air is introduced into the first tank, it

passes through the sieve and N2 is adsorbed. The remaining O2 and

Argon are piped to a buffer or storage tank. Just before the

first tank becomes completely saturated with N2, feed air is

redirected to the second tank which then repeats the above

process.

The first tank is then vented to atmosphere which allows the

N2 to desorb or release from the sieve. To complete the

regeneration of the first tank, a small amount of O2 is used to

purge it.

2. About O2 VPSA Generator

The VPSA process uses ZMS (Zeolite Molecular Sieve), which

attracts (absorbs) nitrogen from air at low pressure and release

(desorbs) it at the vacuum pressure. ASPE system completely

designed as ZMS to be a semipermanentely used without

replacement.

Application

Hospital, Fish Farm, Complete combustion, Ozone, Fermentation,

Sewage Treatment plant,

cutting/brazing

1. Blower

Blower is he equipment used to produce supplied air. supplied

ai is used for separating oxygen from air.

2. Afer-cooler

The purpose of after cooler is of reduce temperature of

supplied air down to ambient temperature.

3. VPSA Generator

In order to separate the oxygen frome the blowing air, ZMS

(Zeolite Molecular Sieve) is used as

adsorbent. VPSA consists of 2 adsorbers. While adsorber "A" is

under the process of Pressurization, production, Purge,

Equilibrium of pressure and Desorption, adsorber "B" is regenerated

to produce oxygen.

4. Vacuum pump

The purpose of vacuum pump is for removing the adsorbed gases

such as nitrogen from the

adsorbent.

5. Oxygen buffer Tank

It plays as a buffer in sending the produced oxygen of low

pressure into the oxygen compressor

stably.

6. oxygen compressor

It is used for compressing oxygen to the extent of what a

user need.

7. After-cooler

The purpose of the After cooler is to reduce the temperature

of compressed oxygen heated in the process of

pressurization.

8. Oxygen storage tank

It is a buffer (storage) tank used to supply the compressed

oxygen with certain pressure, purity and flow.

9. LCP

LCP has control of the whole system into operating

automatically or manually. It also indicates purity, pressure and

flow of the produced.

10. Oxygen supply

The purity of the produced oxygen is 90-95%, Flow and

pressure depend on customer's needs.

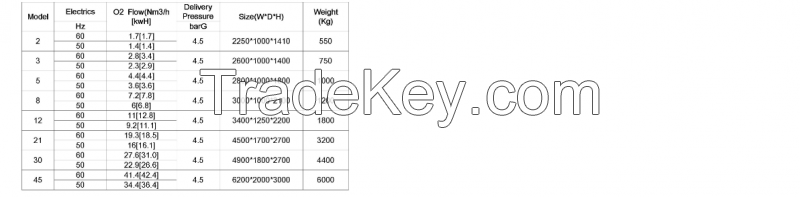

Spec

* Calculated based on data listed below

* Various models are available with different options. Please

contact us for further details

-Electricity: 380v(220v) / 60Hz(50Hz) /3phase / 4

pole: ANYOXY-2 ~ANYOXY-12

380v / 60Hz(50Hz) / 3 phrase / 4 pole: ANYOXY-21 ~

ANYOXY-45

-VSA Type Available

-Capacity: up to 2000 Nm3/h available

ETC

Application code : ASME

| Pays: | South Korea |

| N ° de modèle: | ANYOXY |

| Prix FOB: | ( Negotiable ) Obtenir le dernier prix |

| Localité: | Republic of Korea |

| Prix de commande minimale: | - |

| Commande minimale: | 1 Unit |

| Packaging Detail: | Box |

| Heure de livraison: | 30 to 45 days |

| Capacité de Fournir: | 999 Unit per Day |

| Payment Type: | T/T |

| Groupe de produits : | Machinery |