Prix FOB

Obtenir le dernier prix( Negotiable )

|1 Set Minimum Order

Pays:

China

N ° de modèle:

SQ-TEI series

Prix FOB:

( Negotiable ) Obtenir le dernier prix

Localité:

China

Prix de commande minimale:

-

Commande minimale:

1 Set

Packaging Detail:

pallet or crate

Heure de livraison:

35 to 55days

Capacité de Fournir:

100 Set per Month

Payment Type:

T/T, L/C, D/A, D/P, Western Union, Money Gram, PayPal, Other

Groupe de produits :

Personne à contacter Sam

Shanghai, Shanghai

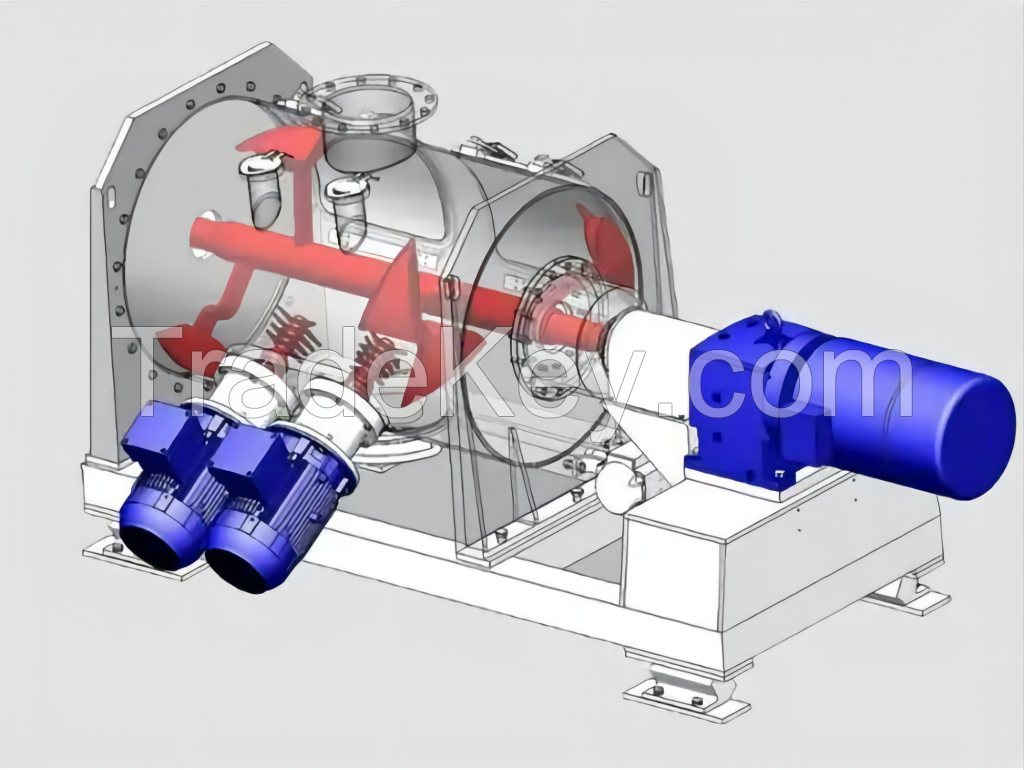

Special Plough Mixer

Working principle

The model is composed of four parts: transmission mechanism,

horizontal cylinder and plow Throwing Knife;Under the action of the

plow, the materials move convective along the cylinder wall. When

the materials flow through the flying knife, they are thrown by the

flying knife rotating at high speed, so as to achieve uniform

mixing in a short time.It can meet most solid-liquid mixing, wet

granulation, drying and other composite processes;It is especially

suitable for the mixing of viscous or colloidal additives.

Features

1. Driving advantage

The standard products are driven by cycloidal reducer with belt

pulley. Compared with the large torque of gear reducer, the elastic

connection of belt transmission has the advantage of protecting

transmission parts in case of overload.

2. Throwing Knife action

During high-speed operation, the plow evenly distributed in the

cylinder can not only disperse the materials axially, but also

carry the animal materials to flow along the circular cylinder. The

flying knife in the middle plays the role of auxiliary mixing and

dispersion and depolymerization of caked materials.

3. Throwing knife shape and speed

The flying knife group of multi-layer blade is directly connected

with the motor, and the standard speed is generally ***0r /

min;According to the difference of material characteristics, the

flying knife has a variety of shapes and speeds.

4. Atomizing nozzle

An atomizing nozzle can be added above the flying knife to realize

liquid mixing. Because the aggregation density of materials at this

position is small under the cutting of the flying knife, the

atomized liquid material is easier to enter and mix with the powder

material.

5. Negative pressure feed

The square door opened on the side of the cylinder can be used for

observation and cleaning. The standard type is equipped with

sealing gasket and the latch is fastened;Travel switch can be

added.

6. Discharging mode

This type of mixer can also be made into a continuous mixer. The

residence time of materials in the cylinder can be controlled by

adjusting the opening size of the discharge valve, so as to control

the mixing uniformity.

Advantages:

1.It is suitable for materials with great difference in specific

gravity and large powder particles;

2.It is applicable to the mild mixing process of powder materials

and will not press feed or break the material particles;

3.No overheating of heat sensitive materials;

4.In the process of mixing powder and powder, it is very convenient

to add liquid required by working conditions or set up one or more

spray port devices.

5.The bottom dislocation valve is convenient for discharging. Since

there is no fixed device at the bottom of the screw, there will be

no pressure feeding

Technical Parameter

| Model / parameter | Volume(M³) |

Loading efficient |

Motor power(Kw) | Overall dimension * maximum diameter * height | Weight(Kg) |

| SQ-TEI*0.1 | 0.1 | 0.**0.6 | 3 | ***0***5***0 | **0 |

| SQ-TEI*0.3 | 0.3 | 0.**0.6 | 4 | ***0****0****0 | **0 |

| SQ-TEI*0.5 | 0.5 | 0.**0.6 | 5.5 | ***0****0****0 | ***0 |

| SQ-TEI*1 | 1 | 0.**0.6 | *1 | ***0****0****0 | ***0 |

| SQ-TEI*2 | 2 | 0.**0.6 | *8.5 | ***0****0****8 | ***0 |

| SQ-TEI*3 | 3 | 0.**0.6 | *8.5 | ***0****5****3 | ***0 |

| SQ-TEI*4 | 4 | 0.**0.6 | *2 | ***0****0****3 | ***6 |

| SQ-TEI*6 | 6 | 0.**0.6 | *0 | ***0****0****8 | ***5 |

| SQ-TEI*8 | 8 | 0.**0.6 | *5 | ***0****0****8 | ***0 |

| SQ-TEI**0 | *0 | 0.**0.6 | *5 | ***0****0****0 | ***0 |

| SQ-TEI**2 | *2 | 0.**0.6 | *5 | ***0****0****0 | ****0 |

| SQ-TEI**5 | *5 | 0.**0.6 | *5 | ***0****0****0 | ****0 |

| Pays: | China |

| N ° de modèle: | SQ-TEI series |

| Prix FOB: | ( Negotiable ) Obtenir le dernier prix |

| Localité: | China |

| Prix de commande minimale: | - |

| Commande minimale: | 1 Set |

| Packaging Detail: | pallet or crate |

| Heure de livraison: | 35 to 55days |

| Capacité de Fournir: | 100 Set per Month |

| Payment Type: | T/T, L/C, D/A, D/P, Western Union, Money Gram, PayPal, Other |

| Groupe de produits : | Mixer |