Prix FOB

Obtenir le dernier prix40000 ~ 60000 USD / Piece

|1 Piece Minimum Order

Pays:

China

N ° de modèle:

1000

Prix FOB:

40000 ~ 60000 USD / Piece Obtenir le dernier prix

Localité:

China

Prix de commande minimale:

40000 per Piece

Commande minimale:

1 Piece

Packaging Detail:

Plastic film for large parts and wooden case for small parts

Heure de livraison:

7 to 10 Days

Capacité de Fournir:

50 Piece per Month

Payment Type:

T/T, Western Union, Money Gram

Groupe de produits :

China

Personne à contacter dahlia

Clarks Summit, Pennsylvania

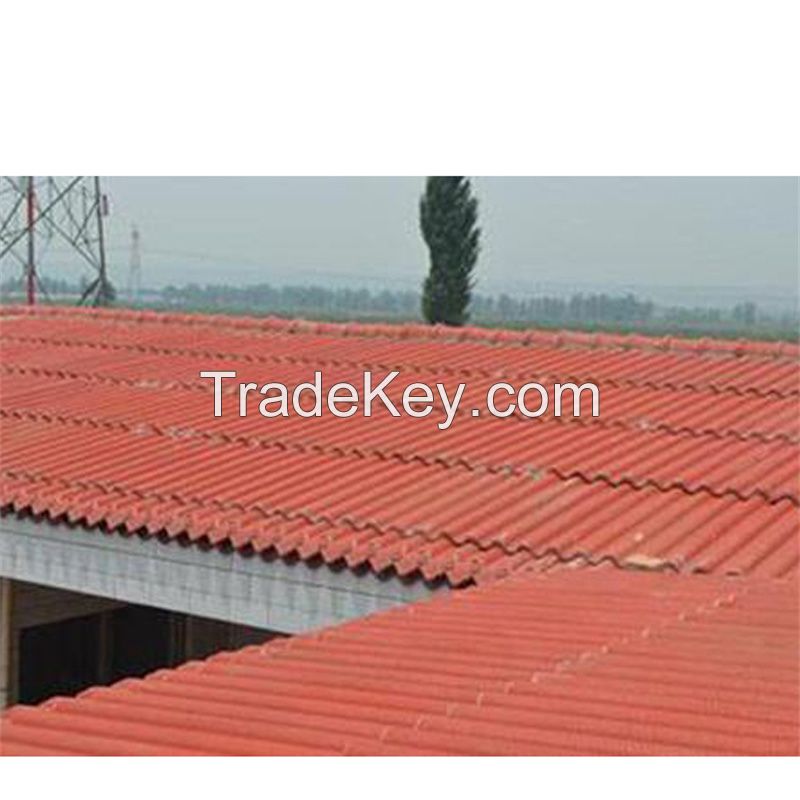

Automatic big cement roof

tile production line​

Introduction to Automatic big cement roof tile production

line:

-Automatic large

cement roofing sheet machine are used to produce large concrete

roof tile for house roof construction.

-The common size for roofing sheet

is 980*640(mm)(Length*Width), 1080*640(mm)(Length*Width),

1230*640(mm)(Length*Width),The thickness can be 10-20mm.

- The

equipmentadoptsfully

hydraulic and pneumatic and PLC programming

control.

-Production

speed can reach 3.5-4

pieces/minuteby

latest hydraulic system,this

equipmenthas

high yield and excellent performance.

-Afterpressing

and filtering, thefinal

roof sheethas

a perfect structure, many varieties, high density, high strength,

precise size,so

itcan

meet the needs of various constructions.

-The

machine can producealsomany

high-grade large color floor tiles, such as terrazzo tiles, washed

tiles, etc. by changing the mold.

-Therefore,Automaticlarge

cement roofing sheet machineis

One ideal advancedconcrete

construction equipment andwelcomed

by cement product investors and users.

parameter data

of Automatic big cement roof tile production

line:

| Name | big capacity cement Roofing Tile molding equipment1230×640 |

|---|---|

| Molding pressure | 1000 tons |

| Molding speed | 3-4 pcs/min |

| Motor power | 11 kw |

| Machine weight | 16 tons |

| Machine dimension | 5200*2000*2650mm |

| Final big cement roof tile size | 1230*640*15mm; 1080*640*15mm; 980*640*15mm |

| Raw materials | Cement ,coarse sand,etc |

The raw materials cement sand with

the ratio of 1:1.5 are sent to the mixer by the bucket elevator for

fully mixing.

Then the concrete is evenly fed to the press machine by doser

machine .

Under the force of the hydraulic cylinder and the mold, the

cement tile product is made.

Then After drying and maintaining, The cement tile can be finally

painting and spraying.

| Pays: | China |

| N ° de modèle: | 1000 |

| Prix FOB: | 40000 ~ 60000 / Piece Obtenir le dernier prix |

| Localité: | China |

| Prix de commande minimale: | 40000 per Piece |

| Commande minimale: | 1 Piece |

| Packaging Detail: | Plastic film for large parts and wooden case for small parts |

| Heure de livraison: | 7 to 10 Days |

| Capacité de Fournir: | 50 Piece per Month |

| Payment Type: | T/T, Western Union, Money Gram |

| Groupe de produits : | Precast equipment |