Prix FOB

Obtenir le dernier prix( Negotiable )

|1 Set Minimum Order

Pays:

China

N ° de modèle:

HNJZ-10

Prix FOB:

( Negotiable ) Obtenir le dernier prix

Localité:

China

Prix de commande minimale:

-

Commande minimale:

1 Set

Packaging Detail:

naked package

Heure de livraison:

30 days

Capacité de Fournir:

50 Set per Month

Payment Type:

Western Union, L/C, T/T

Groupe de produits :

Personne à contacter Ms. Jinzhen

East Jinshui Road, Shanghai, Shanghai

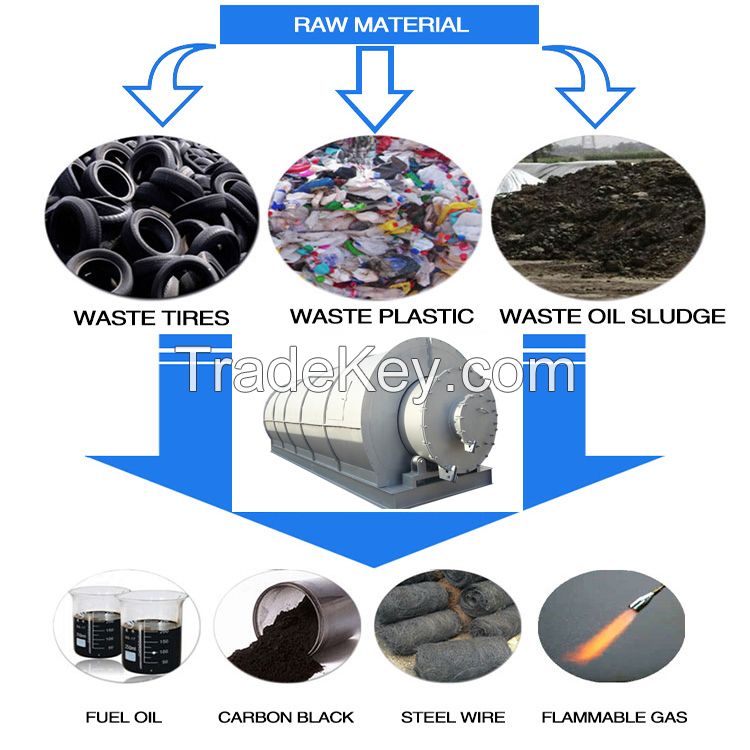

5ton 10ton 20ton Used Tyre

Waste Tire Pyrolysis Recycling Plant for making fuel

oil

Waste plastic tyre pyrolysis equipment will extract fuel oil from

waste (waste tires, rubbers, plastics, soles, life garbage, cable

skin and so on ) from waste rubber to energy, pyrolysis machine.

seperating crude carbon black, steel wires. the sync gas produced

can also be recycled to use as fuel to heat reactor.

Technical Specification

| Product Name | Tyre Pyrolysis Machine |

| Capacity | 5TPD, 6TPD, 8TPD, 10TPD, 12TPD, 15TPD |

| Reactor Material | Q345R, Alloy Steel, Stainless Steel |

| Reactor Thickness | 16.45mm, 18.45mm |

| Total Weight | 30-40 tons (Varies by Design and Capacity) |

| Working Power | 15-30KW(Varies by Design and Capacity) |

| Labor Qty Require | 2-4 Persons for per set machine, more machine, fewer labors |

| Processing Time | Feeding 2 Hours, Processing 8-9 hours, Carbon Black and Steel Wire Discharging 1.5 hours. (Take 12TPD capacity as example) |

| Application Material | Waste Tyre, Waste Rubber, Waste Plastic, Waste Oil Sludge, Waste Aluminum Foil, Waste Cable, Waste Leather, Waste Acrylic(PMMA),etc... |

| Heating Fuel | Pyrolysis Oil, Natural Gas, Electricity, Coal, Firewood, etc... |

| Pays: | China |

| N ° de modèle: | HNJZ-10 |

| Prix FOB: | ( Negotiable ) Obtenir le dernier prix |

| Localité: | China |

| Prix de commande minimale: | - |

| Commande minimale: | 1 Set |

| Packaging Detail: | naked package |

| Heure de livraison: | 30 days |

| Capacité de Fournir: | 50 Set per Month |

| Payment Type: | Western Union, L/C, T/T |

| Groupe de produits : | Waste Tyre Pyrolysis Plant |